Shoe Heat Resistance Tester UI-FT28

Description

Shoe Heat Resistance Tester is to test shoe outsole and upper hot contact resistance ability especially for safety shoe. Heat Resistance Test Method includes ISO 20344, SATRA TM49, EN 344 and etc.

Heat Resistance Test Procedure

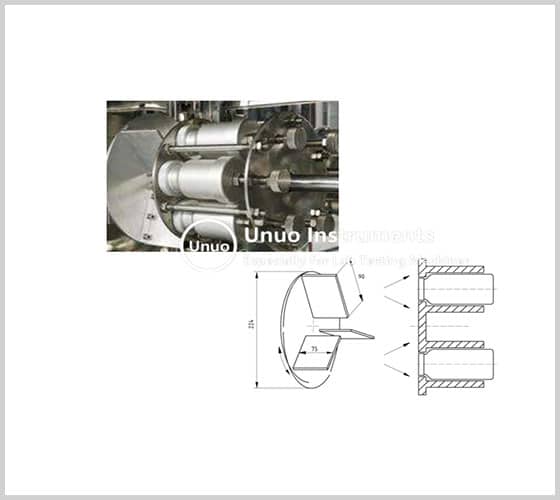

Press the constant temperature metal block which is made of copper on the Sample to check if the sample surface would be damaged or not.

This shoe hot contact resistance tester is equipped with a temperature indicator to display the temperature while on the moving arm, there is a weight to make sure the sample is applied with same pressure.

Warm tip: as toxic fumes might be released from some soling during the test, it is necessary to place the shoe heat resistance tester in a well ventilated area.

Unuo is manufacturer of footwear testing machine for shoe flexing machine, water penetration tester. Contact Us Today for the price & more details. Here for more ISO 20344 Safety Shoe Testing Machine.

Shoe Heat Resistance Tester Specification

| Model | UI-FT28 |

| Cylinder | Mass 200±20g, Lower end surface 25.5 x 25.5 mm |

| Metal Block | 530±50g |

| Temperature | RT~400°C |

| Test Pressure | 20±2kPa |

| Power supply | 1∮AC 220V 50/60HZ 3A |

| Standards | EN 344, QB/T 2926-2007, QB T1807, EN-344-1 section 5.18, SATRA TM49, GB/T 20991 section 8.7, AS/NZS 2210.2 section 8.7, ISO 20344 section 8.7, BS 5131 Part2.11 |

Additional information

| 1. Know More | Shoe Heat Resistance Tester is to test shoe outsole and upper hot contact resistance ability especially for safety shoe. Heat Resistance Test Method includes ISO 20344, SATRA TM49, EN 344 and etc. |

|---|