1. What is a Laboratory Padder? A laboratory padder (also called a lab padder or…

ASTM D1894 Coefficient Of Friction Test | COF – Unuo

Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting – ASTM D1894

ASTM D1894 is to test the kinetic coefficient of friction and static coefficient of friction(starting and sliding friction) of plastic film and sheeting when they slide against themselves or other materials at the test conditions.

1. COF Definition

Friction, n—resistance to relative motion between two bodies in contact.

1.1 Kinetic Friction Coefficient

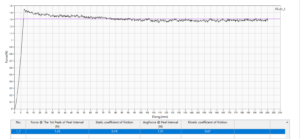

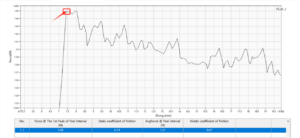

The kinetic friction coefficient is the ratio of the force required to maintain relative motion between two surfaces (kinetic friction force) to the total normal force acting perpendicularly between them. Note: Since kinetic friction typically fluctuates during movement, a high-precision force sensor and a high-frequency control system should be used to capture the average force over the entire sliding process intelligently.

1.2 Static Friction Coefficient

The static friction coefficient is the ratio of the force required to initiate relative motion between two surfaces (at the instant movement begins) to the total normal force acting perpendicularly between them. Note: Static friction occurs at the initial moment of displacement and is generally represented by the peak force observed at the start.

2. Importance of Testing Coefficients of Friction for Plastic Film and Sheeting (ASTM D1984)

Testing the coefficient of friction (COF) of plastic film and sheeting is important because it affects how these materials handle and perform in real-world use. COF measures how easily plastic slides over itself or other surfaces. A low COF means the material is slippery, while a high COF means it has more grip.

This test helps manufacturers ensure quality and safety. For example:

If plastic film is too slippery (low COF), stacks of bags or sheets may slide apart, causing handling problems.

If it’s too sticky (high COF), machines may struggle to move the material smoothly, leading to production issues.

ASTM D1984 provides a standard way to measure COF under controlled conditions. By following this test, companies can improve product performance, reduce waste, and prevent problems in packaging, transportation, and storage.

3. Coefficient Of Friction Testing Machine Applications:

3.1 Plastic Films & Sheets

3.2 Paper & Paperboard

3.3 TRextiles & Nonwovens

3.4 Rubber

3.5 Metal Foils & Products

3.6 Printed Materials

4. Coefficient Of Friction Test Procedure Overview

4.1 Sample Preparation

Samples should be cut to 200mm × 100mm (adjust size if needed to cover the slider surface), ensuring a flat, wrinkle-free, and uncontaminated surface.

For sheet materials, cut 63mm × 63mm specimens and fix them to the slider base using double-sided tape, aligning the material direction with the sliding direction.

4.2 Environmental Conditioning

Condition samples at 23±2°C and 50±5% RH for at least 4 hours to minimize the influence of temperature and humidity on frictional properties.

4.3 Sample Mounting & Setup

Secure one sufficiently large sample flat on a smooth, horizontal test platform, ensuring its long edge aligns with the sliding direction.

Fix the counterpart sample on the slider base using adhesive tape or clamps to prevent loosening during contact.

4.4 Equipment Configuration

Normal Force: Apply a 200±5g vertical load (achieved via slider weight) as per standard requirements.

Sliding Speed: Set to 150±30 mm/min, and calibrate the instrument’s force measurement system.

4.5 Test Execution

Static Friction Coefficient (μs):

Place the slider at the center of the test platform sample.

Gradually apply horizontal force and record the maximum initial force required to initiate sliding (static friction force).

Kinetic Friction Coefficient (μk):

Maintain a constant sliding speed and record the average force during the stable sliding phase (kinetic friction force).

Ensure a sliding distance of ≥130 mm, then reset the equipment.

4.6 Data Calculation & Reporting

Friction Coefficient Calculation:

Static Friction Coefficient (μs): μs = Static Friction Force (Fs) / Normal Force (N).

Kinetic Friction Coefficient (μk): μk = Kinetic Friction Force (Fk) / Normal Force (N).

4.7 Repeatability & Result Handling:

Perform at least 3 parallel tests per sample set; report the arithmetic mean as the final result.

Calculate standard deviation to ensure data repeatability meets standard tolerances (typically within ±15%).

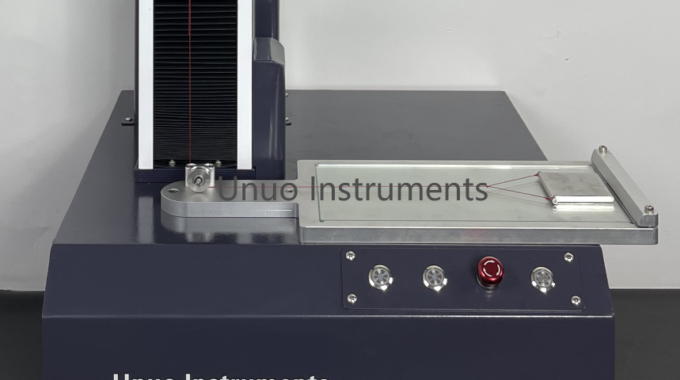

5. Unuo Instruments’COF Testing Machine Features

5.1 Our friction tester delivers accurate, repeatable results for plastic film and sheeting testing with:

- Servo motor drive for smooth, precise speed control

- Ball screw mechanism ensuring consistent movement

- High-precision load cell for reliable force measurement

- Integrated smart controller for automatic data processing

5.2 coefficient of friction tester Key testing capabilities:

- Captures peak static friction force at movement initiation

- Tracks dynamic friction changes during sliding

- High-speed data sampling (force & displacement)

- Automatic calculation of average kinetic friction

5.3 The system’s advanced design meets ASTM D1894 requirements while providing:

✓ Laboratory-grade accuracy

✓ Consistent test repeatability

✓ Simple operation

✓ Reliable COF (coefficient of friction) data

Perfect for quality control and R&D in packaging, films, and flexible materials testing.

6. Important: Coefficient Of FrictionTest Surface Condition Control

Avoid fingerprints, oil stains, or uneven lubricant distribution on samples, as these may cause data fluctuations.

If the test platform sample has wrinkles:

• Use double-sided tape on both edges

• Gently stretch the sample for smooth attachment to the platform