Demattia Flex Tester UI-FT33

Description

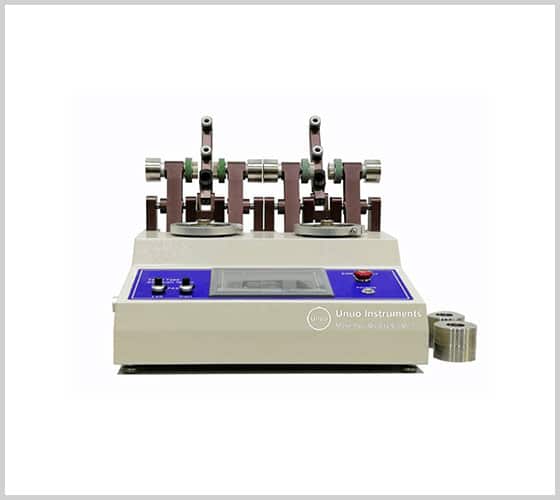

Demattia Flex Tester, also named as Demattia Flex-Cracking Tester, is used to test rubber flexing cracking and crack growth under repeated bending or flexing. Demattia flexing fatigue tester meets test methods of ASTM D813, GB/T 13934, HG 2873, ISO 132:1999(E), BS 903-A10 and etc.

1. Unuo Demattia Flex-Cracking Tester Features:

- 6 or 12 test positions;

- Can be made according to different test standards;

- Piercing tool is supplied.

- Preset test cycles function; When this Demattia machine reaches its preset test cycles, it will auto-stop.

>>>>>>>>Contact Unuo Team Today for De Mattia Flex Tester Price

2. What is the Use of Demattia Flex Tester?

De mattia flex tester is used to test rubber resistance to the formation and crack growth by flexing the samples at a high speed(5Hz, 300cpm). Its application samples include Rubber, vulcanized or thermoplastic, etc. If for crack growth test, a cut by piercing tool is needed to make the cut growth possible. Find out more: Rubber Testing Machine Footwear Testing Machine

3. Demattia Flex-Cracking Tester Principle

Fix the test sample (with required cut length, cut chisel is provided) on the Demattia tester. The cut position should be parallel to the flexing axis. Start the machine and check the cut length change at frequent intervals. Here for more flexing tester.

4. Key Components of the Demattia Machine

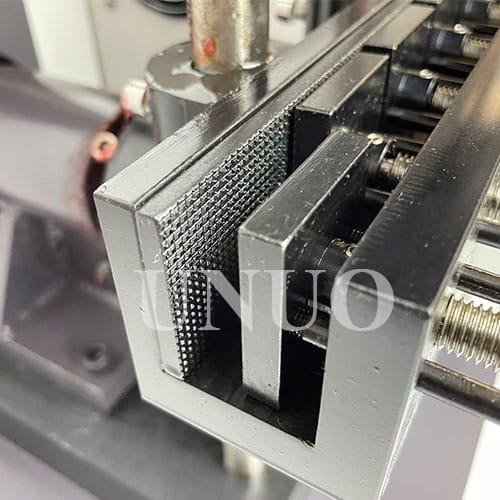

- Grips: the grip surface is made with a pattern, increase the clamping force to firmly clamp the sample and avoid slipping off. Besides, it should be able to open for a certain distance to accommodate sample thickness;

- Controller: the controller is a button control one and is easy to operate. Preset test cycles and present tested cycles are displayed. With timing function and SV, PV values, it makes the interval inspection record easier;

- Driven motor: the motor is to drive the machine flexing. Unuo Instruments uses brand motor to ensure its service life and test stability.

- Belt: belt is driven by motor and is responsible for driving the movement of all movable parts. Unuo uses high quality belt for the De Mattia Flex Machine.

- Connecting Rod: the grips will move up and down along the connecting rod. It needs regular lubrication for maintenance.

5. Unuo Demattia Flex Tester Specification

| Model | UI-FT33 |

| Grips | 6 or 12 groups |

| Stroke | 57mm |

| Speed | 300±10 cycles/min |

| Counter | LCD display, 0~99999999 can be set |

| Power | 1∮ AV220V 50Hz |

| Standards | ASTM-D813, GB/T 13934, HG 2873, ISO 132:1999(E), BS 903-A10: 1999, JIS K6260-1999, JIS K6301, CNS 10017-2007 and etc |