1. What is a Laboratory Padder? A laboratory padder (also called a lab padder or…

Martindale Abrasion Test Procedure

- Introduction:

Martindale Abrasion Tester is used to test the abrasion resistance ability of insole, leather, textile and etc to defined cycles by rubbing in Lissajous figure.

- Martindale Abrasion Test Procedure:

-Principle: Using a Martindale Abrasion Tester, standard wool or sandpaper is used to apply a specified pressure to the sample, and the sample is rubbed in various directions by a Lissajous curve to test the wear resistance of the material.

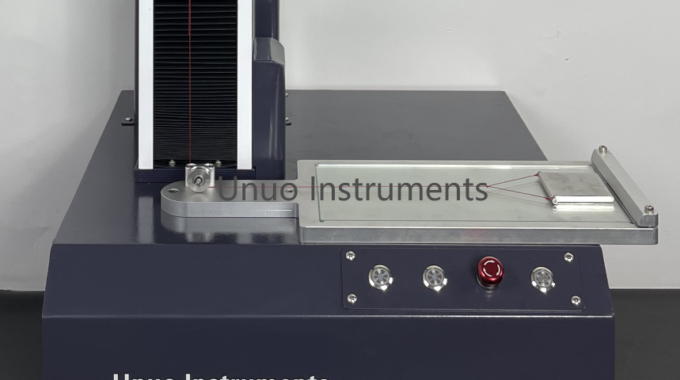

-Machine: UI-FT19 Martindale Tester; check the specification in our catalog

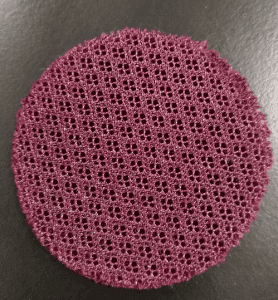

-Sample Cutter: UI-TX16 circular sample cutter; 38mm & 140mm

-Sampling and environment: For each dry friction test and wet friction test, no less than 2 test samples per group, use a circular sampler (38 mm diameter) to take no less than two test samples from different locations of the material to be tested. In the case of woven fabrics, the warp or weft of any two specimens should be different. When sampling from patterned materials, each pattern should be tested. When evaluating the damage or discoloration of the sample, the original sample should be retained in advance, and the comparison should be evaluated after the test. Pre-test samples shall be placed in a standard environment (eg, temperature 23 ± 2 ° C, humidity 50 ± 5%) for at least 24 h and tested in this environment.

–Martindale Abrasion Test Method

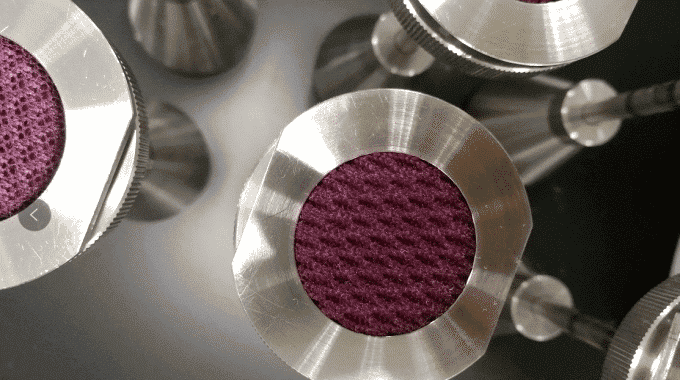

Dry friction test: the sample is fixed on the fixture, and the surface to be rubbed is facing outward. If the unit mass of the test material is less than 500g/m2, it is necessary to add a backing foam of the same size as the sample between the test sample and the grinding head. After the sample is clamped, the sample is inspected for no slack, wrinkles, distortion and the like.

The wool felt is placed flat on the grinding table, the standard abrasive fabric is placed flat on the felt, and the standard abrasive fabric is flattened with the felt using a 2.5 kg compact, and no wrinkles or distortions are formed, and the felt and the abrasive fabric are fixed.

The grinding head was mounted on a Martindale and the sample was in contact with the abrasive fabric. Apply 12kpa pressure to the grinding head, turn on the power, set the number of rotations. When the number of rotations reaches the specified number of times, the instrument stops, and the operator checks the test sample. Under normal circumstances, the detection interval is 1600, 3200, 6400. 12800, 25600, 51200 times, respectively, to check the extent of damage and color change of the test samples.

Wet friction test:

Using high pressure water flow to spray back and forth on both sides of the abrasive fabric and felt until the color is evenly deepened and saturated. The abrasive fabric and felt are installed in the same way as the dry friction test. According to the standard number of rotations, the rewetting treatment should be carried out. The way to return to the wetness is to continue to fix the abrasive fabric and felt on the grinding table, and slowly pour the purified water on the abrasive fabric and felt surface. Gently wipe the water with your fingertips. When the abrasive fabric and felt are evenly darkened, stop absorbing water, and if there is excess water on the surface, remove excess water, place the briquettes on the abrasive fabric for 10S, then remove. Then install the abrasive fabric on the tester and continue the test.

The re-wetting rotation interval is generally 6400, 12800, 25600, 38400 times. The degree of damage and the degree of color change of the test sample were check for every stop.

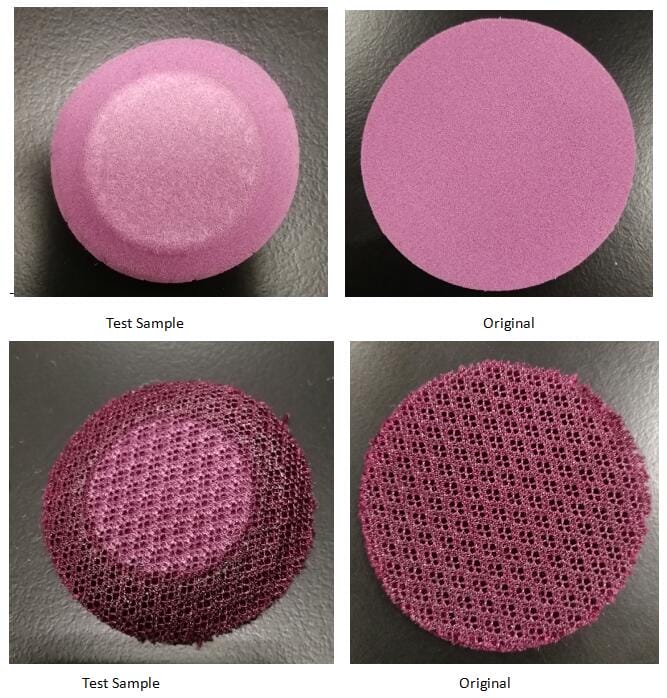

3. Comparison: Test Sample & Original Sample

4. Martindale Abrader Use Precautions

1. Unpacking inspection, when receiving the equipment, unpacking and checking whether the equipment is in good condition.

2. Turn on the power (single-phase AC220, 50/60Hz) to check whether the device runs good. If it can’t run, check if machine is connect with power properly or not. After the inspection, it can’t run, contact the manufacturer.

3. After turning on the power, please check if the moving plate above the device is installed well. Pay attention to see if the three rotating moving axes are in the long slot of the moving plate.

4. For the first time use, do not install the fixture first, carry out no-load operation, check whether the status and sound of the equipment are normal. If there is any abnormality, please contact the manufacturer.

5. Perform simple parameter verification on the equipment.

Speed check, remove the moving board, use the tachometer to measure the external rotating device of the three rotating devices on the device to reach (48 ± 2) r / min, if the speed is wrong, please contact the manufacturer.

6. Lissajous curve inspection (interval wipe). Tools, brushes always (available for purchase)

Place a piece of white paper on the grinding table, use a circular sampler to take a white paper with a diameter of 140mm, place the brush in the sleeve, start the instrument, and stop when running a complete Lissajous curve (16 times). Check whether the Lissajous curve on the white paper is (60±1mm)×(60±1mm), whether the curve distribution is uniform, and there is no mutual overlap or uneven spacing. If there is a phenomenon of Lissajous figure asymmetry, contact the manufacturer.

Thank you for reading. This article is for reference. The final interpretation of this article is Unuo Instrument Co., Ltd.

Email: info@unuo-instruments.com Whatsapp: + 86 15205060783