Martindale Abrasion Tester UI-FT19

Description

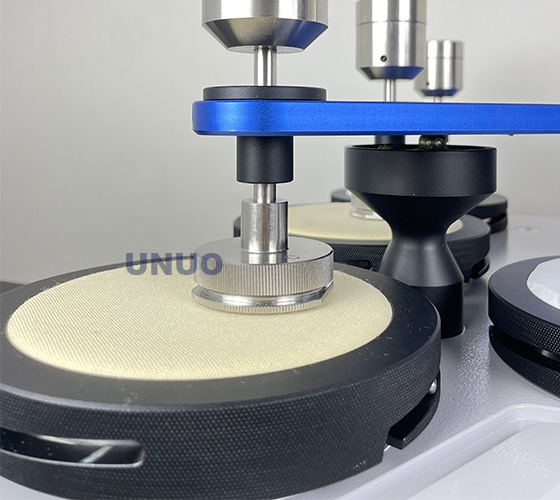

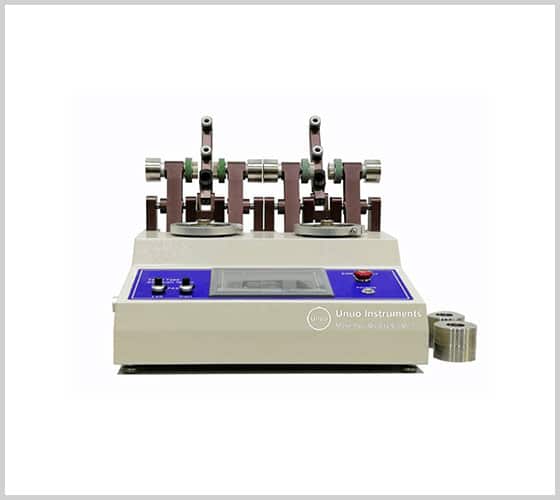

Martindale Abrasion Tester is a versatile machine for textile fabric wear and pill durability evaluation by rubbing the sample against the standard abradant fabric with a certain pressure moving in Lissajous curve under wet or dry conditions. Unuo is a professional Martindale abrasion & pilling tester manufacturer and supplier, serving laboratories and customers over 30+ countries.

1. Why Choose Unuo Martindale Abrasion Tester?

- Various working positions are available, including 4, 6, 8, and 9 positions. You can select the right one for your lab daily test volume and space requirements.

- Full-color touch screen control, both English and Chinese languages supported.

- Servo motor-driven, which ensures the Martindale machine runs at a stable and consistent speed.

- Key components of this Martindale tester are made of stainless steel, which is rust-proof and durable, perfectly meeting the wet abrasion requirement, exposed to moisture.

- The top moving plate is made of aluminum alloy, robust & rust-resistant, which will not distort.

- The top moving plate can be optionally upgraded to One-touch Lift. The compressed air-driven system provides effortless access for abradant changing, sample clamping, and retrieval, significantly reducing manual handling. User-friendly and labor-cost saving.

- Each position has a separate counter.

- Test speed is adjustable for different test standards’ requirements

- The Martindale abrasion machine is capable of 2 types of Lissajous curves in 24mm & 60.5mm

- Easy maintenance. Simply remove the top moving plate for direct access to the lubrication points.

2. The Working Principle of Martindale Abrasion and Pilling Test

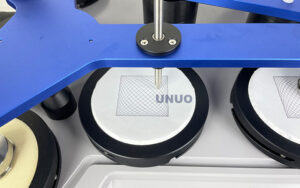

Both Martindale abrasion and pilling tests rub the sample against standard abradant fabric in a Lissajous curve. The abrasion test uses a larger Lissajous 60.5mm while the pilling test uses a smaller one 24mm. Why Lissajous curve important? Rubbing in Lissajous curve, the Martindale abrasion tester will rub the sample in all direction. It simulates the real-lift wear abrasion.

For pressure, Martindale fabric abrasion test normally rubs with 9Kpa, while footwear materials like leather and vampss are tested at 12 Kpa. Martindale Pilling test normally rubs with pilling grip itself weighing 155g. However, some test standards for upholstery fabrics used in furniture would require an extra weight to be a total of 415g, like ISO 12945-2, GB/T 4802.2, ASTM D4970

3. Unuo Martindale Tester System

Unuo Martindale abrasion tester is built with heavy-duty metal abrasion platform, a reliable clamping system, and a high-precision servo motor driven system, micro-computer control system, touch screen display system. Together with all these parts, our Unuo Martindale abrasion tester is guaranteed to run smoothly, making every day’s test setup easier and ensuring accurate test result reading.

4. Unuo Martindale Abrasion Tester Standard Accessories

- Abrasion grip

- Pilling grip if pilling function is needed

- Weight for 9Kpa & 12Kpa

- Press plate

- Pen for Lissajous curve calibration

5. Optional Martindale Abrasion and Pilling Test Consumables

- EMPA 990 pilling photographs – Woven 991 + Knits 992

- SM 50 pilling grading photographs of woven fabric – IWS + ASTM

- (Twill/white, Twill/black, blanket&plain weave)

- Standard fabric

- Standard wool felt

- Socks holder for EN13770

- Clamping rings

- Backing foam

6. Martindale Abrasion Machine Specification

| Model | UI-FT19 |

| Sample size | Diameter 38mm |

| Control Method | Button control / Touch screen control |

| Test Positions | 4, 6, 8, 9 |

| Size of abrasion head | 28.66 ± 0.25mm (Exposed area of specimen holder: 645±5mm2) |

| Pressure | 595 ± 5g (9kPa) ; 795 ± 7g (12kPa) |

| Speed | 47.5 ± 5 r/min |

| Press Weight | 2.5±0.5kg;diameter:120±1mm |

| Size of Lissajous figure | 60±1mm, 24mm |

| Diameter of abrading base | 125±5mm |

| Power | 1∮ 220V |

7. Martindale Abrasion Test Standards by Application

7.1 Textile & Apparel Standards

- ISO 12947: Textiles – Determination of the abrasion resistance of fabrics by the Martindale method.

- ISO 12945-2: Textiles – Determination of fabric propensity to surface pilling, fuzzing or matting – Part 2: Modified Martindale method.

- ASTM D4966: Standard Test Method for Abrasion Resistance of Textile Fabrics (Martindale Abrasion Tester Method).

- ASTM D4970: Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Martindale Tester.

- GB/T 21196.2: Textiles – Determination of the abrasion resistance of fabrics by the Martindale method – Part 2: Determination of specimen breakdown.

- GB/T 4802.2: Textiles – Determination of fabric propensity to surface pilling, fuzzing or matting – Part 2: Modified Martindale method.

- GB/T 13775: Cotton, linen, man-made fiber blended woven fabrics – Determination of abrasion resistance.

- JIS L1096: Testing methods for woven and knitted fabrics.

- IWS TM 112 / TWC 112: Abrasion Resistance of Woven Wool Fabrics.

- IWS TM 196: Pilling of Wool Fabrics (Martindale Method).

- SN 198529 / SN 198525: Textiles – Abrasion and Pilling resistance – Martindale method.

- ISO 12945-1: Textiles – Pilling box method (Related).

7.2 Footwear & Leather Standards

- ISO 20344-2021 Item 6.12: Personal protective equipment – Test methods for footwear (Abrasion resistance).

- ISO 17076-2: Leather – Determination of abrasion resistance – Part 2: Martindale ball plate method.

- BS EN 13770: Textiles – Determination of abrasion resistance of knitted footwear – Martindale method.

- BS EN 13520-2002: Footwear – Test methods for uppers, lining and insocks – Abrasion resistance.

- SATRA TM31 A/B: Abrasion resistance – Martindale method.

7.3 Upholstery & Furniture Standards

- PV 3928: Upholstery cover materials – Abrasion resistance (Martindale test).

- M&S P19C: Abrasion Resistance (Martindale) for Upholstery.

- CEN/TS 16611: Furniture – Assessment of the surface resistance to micro-scratching.

- BS EN 16094: Laminated wood flooring – Test method for the determination of micro-scratches.

7.4 Protective Gear & Coated Fabrics

- EN 388 Section 6.1: Protective gloves against mechanical risks – Abrasion resistance.

- ISO 5470-2: Rubber- or plastics-coated fabrics – Determination of abrasion resistance – Part 2: Martindale abrader.

- P19A: Abrasion Resistance for Coated Fabrics.

7.5 Specific Brand Standards

- M&S (Marks & Spencer): P17, P18C, P19.

- Next: Next 18 (Abrasion), Next TM26 (Pilling).

- PUMA: PUMA Standard Test Methods for Materials.

8. FAQ

8.1 Wyzenbeek VS Martindale

Both of Wyzenbeek abrasion and Martindale abrasion are commonly used in upholstery fabric. For the motion, Wyzenbeek abrasion will rub fabric back and forth while Martindale abrasion will rub fabric in Lissajous curve. For the abrasion, wyzenbeek would rub the fabric weft and warp separately while Martindale would rub in all direction

8.2 Martindale Abrasion Test Procedure

Martindale test procedure can refer to this article. Martindale Test Procedure

8.3 Martindale Abrasion Test Report

A test report needs to include the test standard reference, wet or dry condition, total number completed, the damage of sample after test, a description of sample, date, any deviation, etc.

8.4 Martindale Rub Test Level for Abrasion Resistant Fabric

Test method and abrasion cycles requirements are different for fabrics used for different usages